Auxiliary Machines

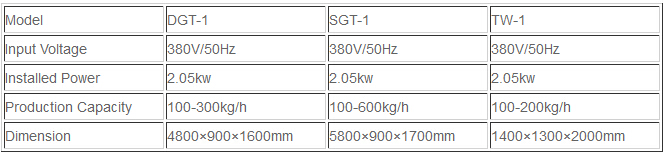

Grinder

It works with all kinds of food and feed processing line. For example, it supplies high fineness powder as the food and fish feed material. It also can work with the nutrition or denaturated starch processing line to guarantee the fineness of final product.

Raw material is delivered to the grinding chamber via hopper by spiral feeder, and is cut and sheared by the high speed cutters, and then the material is moved into the whirlwind separator and the sack dust catcher by the catcher by the negative pressure sucking method. The ejection material meets the product requirement.

Double Roller Flavoring Line

- 1.Wided Application. it could be used to favor many kinds puffed snack,fried snack,fried nuts,pet food fish feed and so on .

- 2. Selection Diversity.We could offer you eight-aquare flovoring machine,Single-roller flavoring machine,Double-roller flavoring machine.And the machines could spray oil and flavoring powder to the surface of food.

- 3.Good Quality.All parts contact the food adopt stainless steel as raw materials Easy to clean, and prevent food pollution .

- 4. Energy Saving.All motors in the machines adopt Chinese famous brand.What's more,we could change it according to your requitements if you need.

Single Roller Flavoring Line

- 1. Wided Application. it could be used to favor many kinds puffed snack,fried snack,fried nuts,pet food fish feed and so on .

- 2. Selection Diversity.We could offer you eight-aquare flovoring machine,Single-roller flavoring machine,Double-roller flavoring machine.And the machines could spray oil and flavoring powder to the surface of food.

- 3. Good Quality.All parts contact the food adopt stainless steel as raw materials Easy to clean, and prevent food pollution .

- 4. Energy Saving.All motors in the machines adopt Chinese famous brand.What's more,we could change it according to your requitements if you need.

Eight Square Seasoning Machine

- 1.Wided Application. it could be used to favor many kinds puffed snack,fried snack,fried nuts,pet food fish feed and so on .

- 2. Selection Diversity.We could offer you eight-aquare flovoring machine,Single-roller flavoring machine,Double-roller flavoring machine.And the machines could spray oil and flavoring powder to the surface of food.

- 3.Good Quality.All parts contact the food adopt stainless steel as raw materials Easy to clean, and prevent food pollution .

- 4. Energy Saving.All motors in the machines adopt Chinese famous brand.What's more,we could change it according to your requitements if you need.

Microwave Dryer

- 1. Microwave dryer is with defrosting, drying, sterilization, ripening, cooking, solidifying, etc. function for cereals, vegetables, dried fruits,seafood, seasonings, snacks, building materials,etc.

- 2. Selective beating. Water molecule strongly absorb microwave. So high water parts absorb more microwave than low water part. Then high-water part is heating more part. This selective heating characteristics make sure material is uniformly heated and uniform dried.

- 3. Water dehydration direction is from inside to the outside, therefore, microwave drying has puffed effect on the subsequent crushing of great help.

- 4.The energy efficient. Microwave directly works on the material, therefore no additional heat loss. Furnace air and corresponding container will not heat to save high thermal efficiency. The production environment is also significantly improved. it can save 30%energy comparing with the infrared heating type.

High Temperature Indflated Oven

- 1. The drying process uses an even circulation of heated air through a bed of material as it is carried through the dryer chamber on a conveyor band.

- 2. The range of band ovens include: single pass and multi-pass units.

- 3 Heating systems can be gas, steam, thermal oil or electric.

- 4. Connecting material part material is stainless steel

- 5. A range of belts is including woven mesh, upwards/downwards airflow, fully insulated panels and doors, variable speed conveyor drives.

Pulverizer

It works with all kinds of food and feed processing line. For example, it supplies high fineness powder as the food and fish feed material. It also can work with the nutrition or denaturated starch processing line to guarantee the fineness of final product.

Raw material is delivered to the grinding chamber via hopper by spiral feeder, and is cut and sheared by the high speed cutters, and then the material is moved into the whirlwind separator and the sack dust catcher by the catcher by the negative pressure sucking method. The ejection material meets the product requirement.

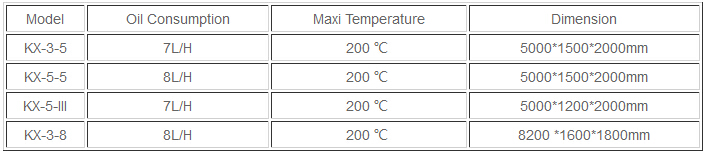

Continuous Fryer

- 1. World-famous Brand Electronic Apparatus ensure the Excellent and Stable Performance.

- 2. Controller Box made of Stainless Steel or Sprayed-plastic(optional), Allows adjust Frying Time by Variable Conveying Speed as required, Alarm Oil Level.

- 3. Double Layer 304 Stainless Steel Belt, Preventing Products Floating, Ensure Complete and Perfect Frying Effect.

- 4. Scrapers fixed on the belt, Make the products come out easily.

- 5. Electric Belt and Upper Cover Lifting Setting, Make Cleaning more Easier and Save Human Power.

- 6. Different Heating Methods Optional: Electricity, LPG, Natural Gas, Diesel etc.

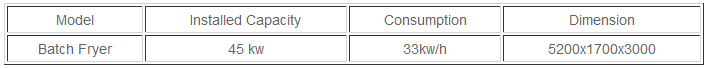

Batch Fryer

- 1.These fryers are constructed of high grade stainless steel, with available stainless steel interconnections and valves.

- 2. State of the art filtration systems are used to ensure proper removal of fines in order to give the maximum life to your cooking oils.

- 3. The most commonly used systems are filter baskets which can filter down to 5 micron.

- 4. The other common system employed is fines removal drums which mechanically separate the oil, literally lifting fine particles out of the cooking oil.

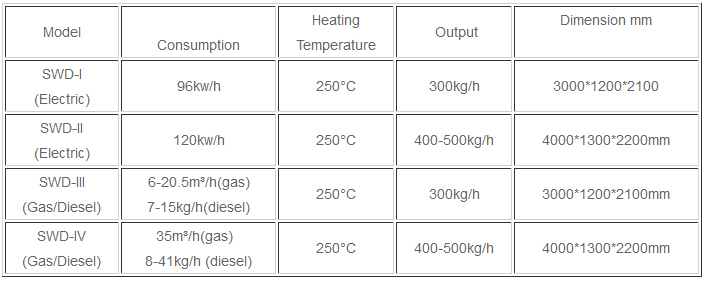

Steam Dryer

- 1. The drying process uses an even circulation of heated air through a bed of material as it is carried through the dryer chamber on a conveyor band.

- 2. The range of band ovens include: single pass and multi-pass units.

- 3. Heating systems can be gas, steam, thermal oil or electric.

- 4. Connecting material part material is stainless steel

- 5. A range of belts is including woven mesh, upwards/downwards airflow, fully insulated panels and doors, variable speed conveyor drives.

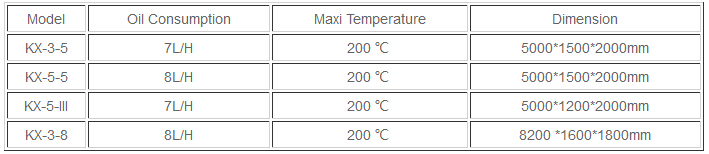

Diesel Dryer

- 1. The drying process uses an even circulation of heated air through a bed of material as it is carried through the dryer chamber on a conveyor band.

- 2. The range of band ovens include: single pass and multi-pass units.

- 3. Heating systems can be gas, steam, thermal oil or electric.

- 4. Connecting material part material is stainless steel.

- 5. A range of belts is including woven mesh, upwards/downwards airflow, fully insulated panels and doors, variable speed conveyor drives.

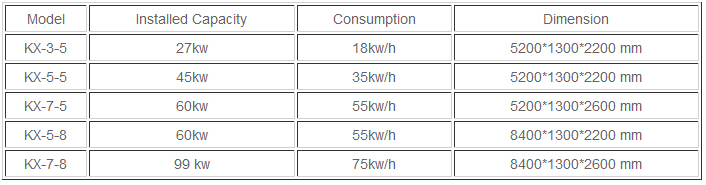

Electric Dryer

- 1. The electric oven uses an even circulation of heated air through a bed of material as it is carried through the dryer chamber on a conveyor band.

- 2. The range of band ovens include: single pass and multi-pass units.

- 3. Heating systems can be gas, steam, thermal oil or electric.

- 4. Connecting material part material is stainless steel.