Eco Friendly Products Processing Line

Eco-Friendly Degradable Rice Drinking Straw Machine

Edible straw is a new type of non-polluting, degradable straw. With the popularity of edible straw in South Korea,global attention has been paid to the product . In order to meet the needs of market , our company developed the machine of edible straw. The main raw materials are corn starch, rice flour, flour and other grain flour. The products are all green, non-polluting and edible.

Main Features :

- The main extruder adopts frequency speed controlling with high automation ,stable and more power saving .

- The screw are made of the alloy steel and special craft ,durable usage ,high pressure,the screw life is longer.Adopting the building block structure and combining willingly according to the different demand.

- The forced lubrication system,can guarantee the equipment transmission life longer.

- Auto-temperature control system makes the temperature control more direct viewing and the parameter more precious .

- Self-cleaning ,when stopping ,it can be cleaned without disassembling.

- According to different screw design rate to meet different technology request.

- This equipment has the wide material ,multi-shape product and flexible collocations.We can produce the different products according to the different models and collocations.

Technical Parameters :

Parameter of pasta straw machine |

||||

Model |

Installed Power |

Power Consumption |

Production Capacity |

Dimension |

EXT 100 |

60kw |

35kw |

100-150kg/h |

3200*1100*1900mm |

TSE 75 |

90kw |

50kw |

300-350kg/h |

3500*1200*2200mm |

Edibe Drinking Straw Production Line

1.1 Edible Drinking Straw Introduction

Edible Drinking Straw is a new type of non-polluting, etable drinking straw. The main raw materials are rice flour and other grain flour. As environmental pollution becomes more and more serious, people are increasingly aware of the importance of environmental protection.Because daily life will produce a large number of plastic straws, causing damage to the environment, so pollution-free degrade straws came into being.

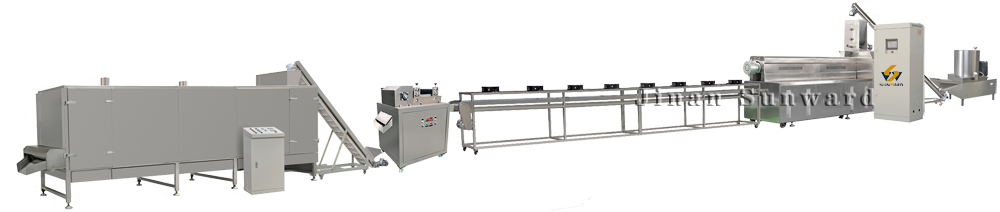

1.2 The Whole Line of Edible Rice Drinking Straw Production

- 1.Mixer

- 2.Screw Conveyor

- 3.Single Screw Extruder Machine

- 4.Cooling & Cutter Machine

- 5.Climbing dryer machine

- 6.Cooling machine

1.3 Voltage

Three phases: 380V/50Hz, Single phase: 220V/50Hz. we can make it according to customers' Local voltage according to different countries.

1.4 Raw Materials

Rice flour and other grain flour.

1.5 Samples

1.6 Client Case Video of Edible Rice Drinking Straw Production Line

Packing and Shipping:

- 1. Testing Machine before package.

- 2. Packaging: inside is covered in plastic film, outside is a wooden case.

- 3. Shipping: 15-35 working days after receiving deposit.

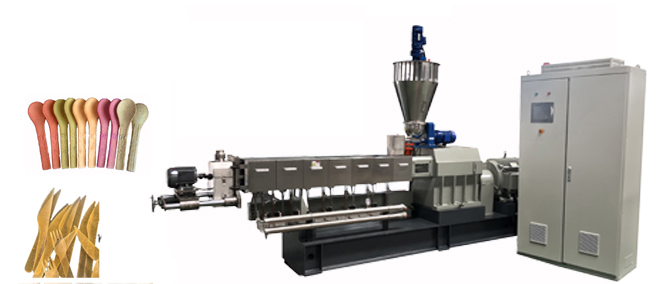

Edible Tableware Machine

Edible utensil is something new which just been researched and developed recently. The original intention of developing it is also considering reduce the pressure of environment. Due to the material of making it is absolutely natural, such as grain flour, natural pigment, so it is biodegradable and also can be eaten. So from now, you can not only eat your food, but also your dinnerware such as fork, knife, spoon, you can not only eat your ice cream, but also it's stick(the ice cream stick also can be made by the machinery).

Sample Picture :

Our Machine :

Technical Parameters :

| Model | TSE-65 | TSE-70 | TSE-85 |

| Installed power | 80kw | 210kw | 210kw |

| Power consumption | 55kw | 75kw | 170kw |

| Production Capacity | 120-150kg/h | 220-260kg/h | 400-500kg/h |

| Dimension | 15*2*3m | 22*2*3m | 30*2*3m |

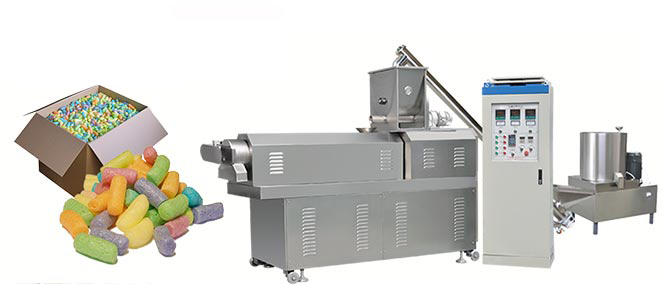

Biodegradable Packing Foam Peanuts Producing Line

Biodegradable filling packing material production line is kind of new application of extrusion technology.

The line uses cheap natural starch, maize/corn starch and tapioca starch as main materials, through extruding treatment process by twin screw extruder, it is processed to kind of starch-based foam material without any additive vesicant which can be fully biodegradable.

Biodegradable filling packing material can be widely used, such as packaging and filling material which can fill in the items packaging space quickly and evenly. It can be used on electrical products, precision instruments etc. since its functions of buffer and shock-absorption. What's more, it can be used as "educational sticky toys” and “DIY corn kernels” etc. After lightly wet, it can be bonded with the other materials, and create infinite styles.

Biodegradable filling packing material is applied widely since it is green, safe for children and environment biodegradable, nontoxic, lightweight, Anti-static etc.

Raw materials:

Maize / Corn starch, Cassava /Tapioca starch, Potato starch

Products of packaging foam peanuts produce machines:

corn starch loose filler, biodegradable packing peanuts, resilient &reusable stuffing materials, water soluble & compostable cushioning materials.

Flow Chart of Packaging Foam Peanuts Produce Machines:

Mixer Machine---Screw Conveyor---Twin-screw Extruder---Air Conveyor---Packing Machine

Sample pictures:

Technical Parameters :

| Model | Installed Power | Power Consumption | Production Capacity | Dimension |

| TSE70 | 70kw | 50kw | 11-15m³/h | 12*1.3*2.2m |

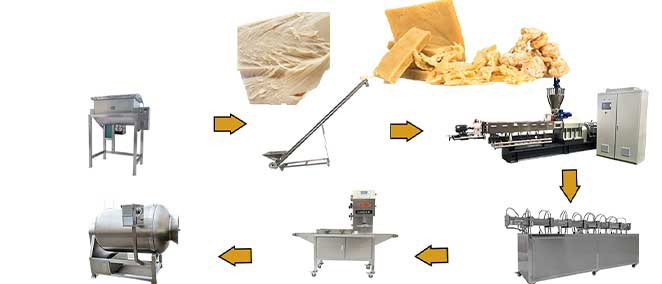

High Moisture Meat Analogue Processing Line

High-moisture protein is a vegetable protein product with a moisture content of ≥50%. The main raw material is vegetable protein extracted from soybeans, peas, wheat and other plants. According to the biochemical composition and three-dimensional structure of meat, modern food processing technology and equipment are used. , which accurately simulates the composition and structure of meat, making it a type of plant-based protein product that has similar characteristics to livestock, poultry, and fish in terms of texture, structure, chewiness, and even flavor. Plant-based meat products feature high protein, low fat, low carbohydrate, 0 cholesterol, and 0 trans fatty acids, helping people transition to a healthier diet. What's more worth mentioning is that compared to meat, plant-based meat can also help reduce environmental damage from the production process. Livestock is the second-largest source of greenhouse gas (GHG) emissions after fossil fuels and a contributor to deforestation, water and air pollution, and biodiversity loss. New research shows that reducing meat consumption and switching to a plant-based diet can reduce our personal carbon footprint by up to 35%, and its products are well-received and recognized by consumers for their delicious, healthy and environmentally friendly properties. Industry insiders believe that the market for plant protein may exceed that of animal protein in the future.

1. Process flow :

Batching---Mixing---Extrusion---Cooling---Shaping---Cutting

Production line flow chart:

Mixer---Screw conveyor---HMMA extruder---Shaper---Cutter

- Mixer: Small production lines can use simple powder mixers, which are characterized by small output and need to match raw materials in a certain proportion manually; large production lines can use automatic feeding system, which is characterized by complete automation (automatic weighing and batching and Mixed materials), the output is large.

- The screw conveyor is used to transfer the processed raw materials from the mixer to the extruder

- The extruder is used to used to reconstitute proteins

- The shaper is used to cool and shape the protein

- The cutter is used to cut protein into different size

2. Parameters

| Model | Installed Power | Capacity | Dimension |

| TSE65-W | 74kw | 100-150kg/h | 15×1.5×2.2m |

| TSE75-W | 160kw | 400-500kg/h | 22×1.7×2.2m |

3. Parts of our machines

4. Samples of high moisture meat analogue