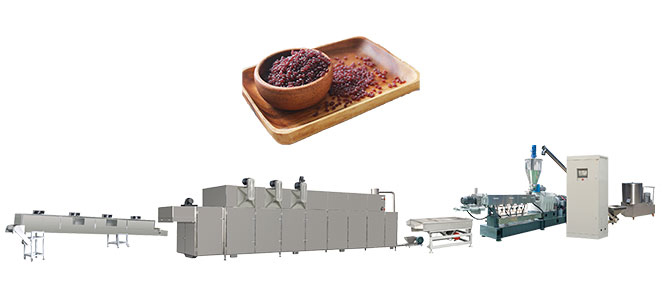

Series of Artificial Rice Processing Line

Fortified Nutritional Rice Processing Line

- 1. The material is extruded into rice shape by the twin-screw extruder, and dried in a rotary dryer to needed moisture content. The extruding technique makes it possible to strengthen and solidify the micronutrient in the rice. This artificial rice can be mixed with natural rice prior to cooking as usual. When cooking is finished, its grains are not broken and there is no difference between the artificial rice and the natural one in viscosity, elasticity and taste.

- 2. The Processing Line adopts broken rice rice, corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient, and some other vitamin and mineral as part of ingredient.

- 3. This line can be used to produce fortified rice, nutritional rice, instant rice, reconstituted rice and other artificial rice.

- 4. Output can be 100kg/h, 200kg/h, 300kg/h, 500kg/h,1000kg/h

- 5. Flow chart: Mixing system---Extrusion system----Drying system---Cooling system---Packing system

- 6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

- 7. All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

Technical Parameters :

| Model | Installed Power | Capacity | Dimension |

| TSE70 | 112KW | 150-200kg/h | 22×1.5×2.2m |

| TSE75 | 160KW | 300-500kg/h | 25×1.5×2.5m |

| TSE78 | 180KW | 600-800kg/h | 25×1.6×2.6m |

| TSE95 | 225KW | 800-1000kg/h | 35×1.8×2.8m |

Fortified Nutrition Rice Plant Designed For India

Nutritionally fortified rice is finished rice made by adding some nutrients that are lacking or specially needed by the human body to ordinary rice. The nutritional fortification of rice contains a variety of vitamins, minerals and amino acids. Nutrient-enriched rice makes the rice nutrition more balanced, can guarantee consumers' basic nutritional needs including micronutrients, and gradually control and eliminate the two major malnutritions, insufficient nutritional intake and nutritional imbalance.

Our company's special policy for the Indian market:

Now, thanks to the support of the Indian government, the upsurge of fortified rice has started in India. As one of the main suppliers of the nutritionally fortified rice plant, our company's orders for fortified rice equipment have skyrocketed recently. Our company opened a green channel specifically for Indian customers, in order to serve Indian customers better:

- 1. Specially designed production line plans for Indian customers.

- 2. prioritized the production of Indian customer orders, and controlled the lead time within 2 weeks.

- 3. provided local after-service for Indian customers, etc.

Features:

Nutrition rice production line is based on food nutritional demand and advanced technology. It is fit for modern enterprise. It has the advantages of high automatic and saving energy. The production line can use various grains such as rice, millet, black rice, buckwheat, as raw materials, add various vitamins, proteins and minerals for processing, squeeze, mature and shape in an extruder to regenerate new fortified rice, Golden rice, buckwheat rice, konjak rice, etc.

Fortified rice production line:

Flow chart:

Grinder---Mixer---Screw conveyor---Rice extruder---Vibrating screen---Air conveyor---Dryer---Cooling Conveyor

Some machines of the production line:

The pictures just for reference, contact us for accurate solution and quotation.

Technical Parameters :

| Model | EXT100 | TSE70-R | TSE75-R | TSE78-R | TSE95-R |

| Installed Power | 112kw | 130kw | 190kw | 210kw | 240kw |

| Capacity | 80-100kg/h | 120-200kg/h | 400-500kg/h | 600-800kg/h | 800-1000kg/h |

| Dimension | 21×1.3×2.2m | 22×1.5×2.2m | 25×1.8×2.6m | 30×2.0×2.6m | 35×2.2×2.8m |

Dal Fortified Rice Processing Line

Dal is a kind of important staple food in South Asian countries and forms an important part of the cuisines of South Asia. So the require amount is large. Our dal machine can make artificial dal with broken dal, dal powder, bean powder, etc. In addition to, another popular food-the fortified rice can also be made by this production line. The raw material of fortified rice kernel can be broken rice, rice powder, corn, millet, wheat, oats, buckwheat, bean and some essential nutrients for the human body.

We are a professional manufacturer of food machinery with nearly 20 years of experience. There are more 1000 users of our machines all over the world. What we can provide for our clients, not only machinery, but also the service of lifetime. Normally we dispatch our engineers to our clients' factory, but now due to the covid pandemic, we established some native service teams in some countries (such as India), and we provide remote online service. So don't worry about how to design the plant, how to install and operate the machines, that are all our work. just tell us what do you want to produce, then we will get the final products from your plant by your workers with our training.

Features:

- 1. Output can be 100kg/h, 200kg/h, 300kg/h, 500kg/h, 800kg/h.

- 2. Flow chart : Mixing system---Extrusion system----Drying system---Cooling system---Packing system

- 3. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

- 4. All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

Technical Parameters :

| Model | EXT100 | TSE70-R | TSE75-R | TSE95-R |

| Installed Power | 93kw | 112kw | 190kw | 240kw |

| Capacity | 80-100kg/h | 120-200kg/h | 300-400kg/h | 500-800kg/h |

| Dimension | 21×1.3×2.2m | 22×1.5×2.2m | 25×1.5×2.6m | 35×1.6×2.6m |

Some machines of the dal and frk plant:

Samples of dal, lentils, fortified rice kernels: