Series of Extruder

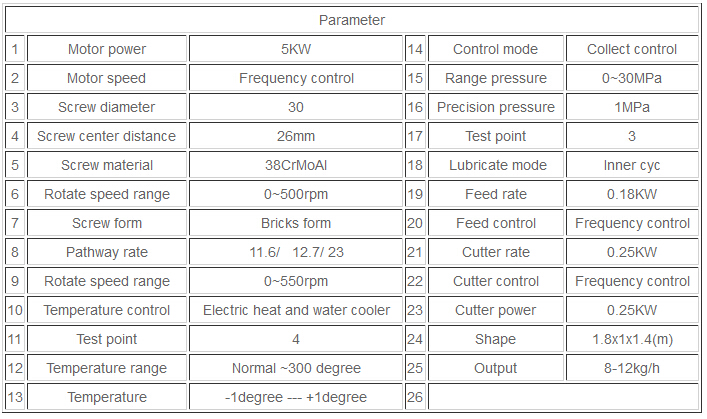

DSE30 Lab Twin-Screw Extruder

Lab twin-screw extruder DSE30 is special for universities, research institutes and large and medium-sized enterprises engaged in various extrusions, extruded maturation, extruded variability study omnipotent models. It has gone through four generations of improvements to adapt to cereals; potato starch, protein, chemicals, plastics, rubber and other raw materials are vastly different for a variety of experiments. Powerful, easy to operate and simply of parameters adjustment, test data accurate, easy maintenance .

Small Single Screw Extruder Machine

- 1. Fish food processing line Description:Fish food processing line is suitable to make dry fish food pellet (catfish, aquarium, Tilapia, Freshwater fish and tropical fish etc.)

- 1). All fish food equipments are made of stainless steel.

- 2). The fish food whole line fully continuous and automatic.

- 3). Sunward Company provide basic fish food receip according to your require.

- 4). The final fish food shapes and sizes can be various by changing the mould.

- 5). Supply different size mould free.

- 6). Packing machine could be supplied to work with the line (depend on your require).

- 2. Raw materials for fish food pellet:Most fish food pellet inculding animal protein and plant protein, Plant protein adopts corn flour,rice flour,wheat flour,soybean flour,peanut cake powder…..Animal peotein adopt fish meal, shrimp meal,crab meal, sleeve-fish meal and so on….you can add other ingredient according to the local fish live require.

- 3. Fish food machine can make the follow fish food Products:This fish food processing line can be used to produce fish food pellets, the pellets size can be from 1.0mm to 9.0mm by adjusting the extruder dies, Meanwhile this line can used to produce dog food, cat food by change some place. You can buy one whole line to make fish food and dog cat food together.

- 4. The fish food extruder machine Capacity:100-150kg/h, 220-260kg/h, 400-500kg/h, 800-1000kg/h

- 5. The fish food processing line (220-260kg/h)Flow chart:Grain grinder---Mixing system---Twin screw Extrusion system----Drying system----Flavoring system--Packing system

- 6. China standard industrial Voltage for the machine:Three phases: 380V/50Hz, Single phase: 220V/50Hz, We can make it according to customers' Local voltage according to different countries (400v 415v 480v…….).

- 7. Machines materials:All the fish food machines are made by stainless steel, this whole line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self- cleaning function.

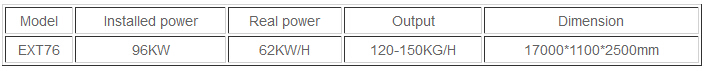

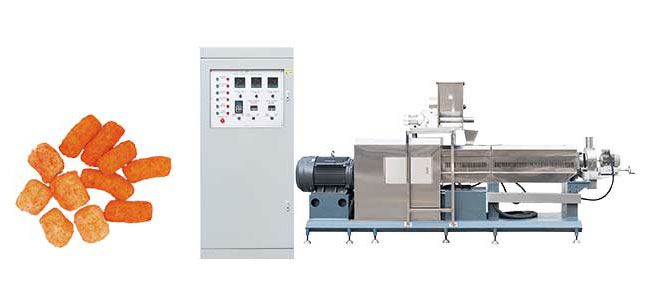

Kurkure Machine

- 1. Nik Naks/Cheetos/Kurkure/Corn curls are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits is moisturized in the flour mixer with water and fed to the Rotary Head Extruder. In the extruder, due to the two rotary plates made of yellow brass, the corn grits are squeezed and twisted to form curls shape. The curls pass through the die and gets cut by the cutting knifes into required lengths.

- 2. Raw materials: adopts corn grits as raw materials meanwhile mixing with water and oil

- 3. Products: This line can be used to produce cheetos, kurkure, and nik naks

- 4. Capacity: 100--150kg/h

- 5. Flow chart: Mixing system---Extrusion system----Baking system (Frying System) ---Flavoring system---Packing system

- 6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

- 7. Machines Materials: All the machines are made by stainless steel

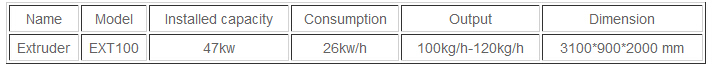

Single Screw Extruder

- 1. Single screw extruder adopts flour, corn starch and potato starch as raw material, makes food through the process of extruding, cooking, shaping, drying and frying. By choosing different dies, different shapes food such as shell, screw, square tube, round tube, lotus root slices etc can be produced. The food is very popular in market. This processing line has the advantage of rational design, high automatic degree and accuracy control.

- 2. The model is EXT100, the output is 100-120kg/h.

- 3. The main body material is stainless steel, which is easy to be cleaned.

- 4. The screws material is 38CrMnAl, which is wear-resisting.

- 5. Our project is turn-key. We will send our engineer to your factory, install and debug the equipments, and train your operators.

- 6. The processing line needs two workers to operate.

- 7. The temperature and rotating speed can be controlled and adjusted.

- 8. The processing line has self-cleaning function.

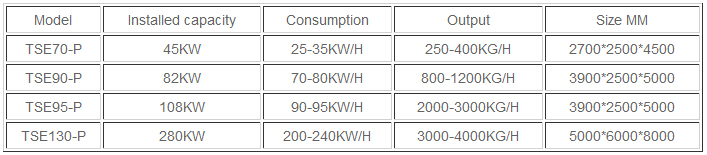

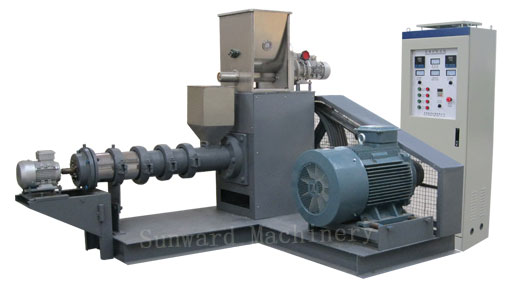

Steam Twin Screw Extruder

- 1. Main driving is high accuracy gearbox and high output

- 2. High efficiency driving, stable and low noise

- 3. Fully stainless steel enlarged conditioner ensures good cooking effect.

- 4. Permanent magnet is available.

- 5. International advance steam fittings and imported pressure reduction valve

- 6. It is widely used for pelletizing high rank poultry & Livestock products

- 7. Floating and sinking fish feed, pet food can be produced with different size and shape.

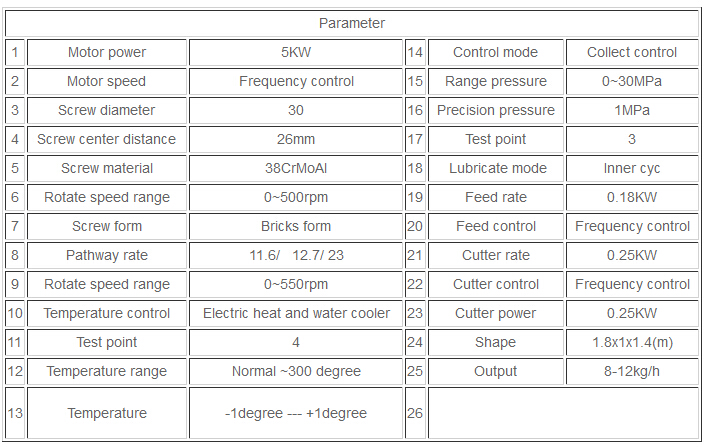

Lab Twin Screw Extruder

Lab twin-screw extruder is special for universities, research institutes and large and medium-sized enterprises engaged in various extrusions, extruded maturation, extruded variability study omnipotent models. It has gone through four generations of improvements to adapt to cereals; potato starch, protein, chemicals, plastics, rubber and other raw materials are vastly different for a variety of experiments. Powerful, easy to operate and simply of parameters adjustment, test data accurate, easy maintenance.

Twin Screw Extruder

- 1. The main extruder adopts frequency speed controlling with high automation and stable per-formation.

- 2. The screws are made of the alloy steel and special craft,durable usage,high pressure,the screw life is longer. Adopting the building block structure and combining willingly according to the different demand.

- 3. The forced lubrication system,so that it can guarantee the equipment transmission life is longer.

- 4. Auto-temperature control system, make the temperature controlling more direct viewing and the parameter more precise.

- 5. Self-cleaning, screws can be cleaned by reputing wasted material.

- 6. According to different screw design rate to full different technology request.

- 7. With different structure, it is used in human food area and pet food area.

Technical Parameters :

| Model

Parameter |

TSE130 | TSE120 | TSE95 | TSE85 | TSE75 | TSE70 | TSE65 |

| Installed powder |

210KW | 160KW | 105KW | 90KW | 85KW | 45KW | 35KW |

| Main motor powder |

190KW | 145KW | 90KW | 75KW | 75KW | 30KW | 22KW |

| Output(kg/h) | 3000-5000 | 2000-3000 | 1500-2000 | 600-800 | 600-700 | 200-250 | 100-150 |

| Dimension(m) | 7.5*2.2*4.2 | 5.2*1.5*3.8 | 4.9*1.4*3.2 | 3.9*1.2*2.8 | 3.8*1.2*2.8 | 2.8*1.0*1.9 | 2.7*0.9*1.8 |

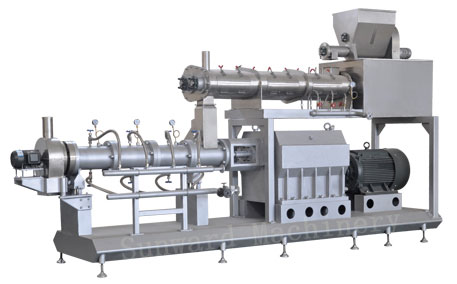

Artificial Nutrition Rice Extruder

Unlike the circular barrel twin screw extruder, this is a new twin screw extruder with a square barrel. Compared with the circular barrel twin-screw extruder, the barrel and screw of this extruder are assembled in the form of building block combination modules, which only need to replace the severely damaged parts, and the square barrel has a bushing, which further prolongs the service life of the barrel. In terms of material, the screw of the new extruder is made of high-strength and high-wear-resistant alloy tool steel Cr12MoV or high-speed steel W6Mo5Cr4V2, which has better hardness and wear resistance; the barrel material is 45# alloy steel, plus there is an extra protection of bushing between the screw and barrel, which makes the barrel life several times longer than that of ordinary barrels. The aspect ratio of the screw is also more reasonable, so the quality of the product produced is higher. As one of the core components of the whole equipment, the gearbox adopts the famous Chinese brand Nanjing gearbox. It is characterized by sophisticated materials, precise assembly, stable operation and long service life.

Other Features:

- The main machine adopts advanced frequency converter speed regulation technology, which makes the equipment powerful, runs more smoothly and saves electricity.

- Forced lubricating system to ensure a longer life of the transmission part of the equipment.

- Intelligent touch screen control system, you can clearly see various working parameters and achieve precise control. Therefore, the resulting product is of higher quality.

- Easy to operate.

- The screw has a self-cleaning function, and it is not necessary to disassemble the screw for cleaning when the machine is stopped.

This is a multifunctional extruder. In addition to producing all kinds of artificial rice (fortified rice, golden rice, nutritious rice, instant rice), it can also produce all kinds of puffed snacks, such as puffed corn balls, corn on the cob, puffed rice, Miao Cuijiao, Cheetos, rice crackers, etc, and pet food.

Technical Parameters :

| Model | Installed Power | Main Motor Power | Capacity | Dimension |

| TSE75-R | 106kw | 55-75kw | 400-500kg/h | 5000×1200×2100mm |

| TSE78-R | 120kw | 75-90kw | 600-800kg/h | 5300×1200×2100mm |

| TSE95-R | 141kw | 90-110kw | 800-1000kg/h | 5800×1300×2300mm |

Three-Screw Extruder

As the name suggests, the three-screw extruder is an extrusion device composed of three screws and a barrel, which is equivalent to the core part of an extruder and determines the production efficiency and use range of the extruder. From single-screw extruders to twin-screw extruders to triple-screw extruders, the performance and output of extruders continue to improve. The three-screw extruder is divided into parallel arrangement and triangular arrangement according to the arrangement of screws. The three screws arranged in parallel will form two meshing surfaces and the three screws arranged in a triangle will form three meshing surfaces. The technical difficulty increases step by step, and the production efficiency also increases exponentially. The three-screw extruder produced by our company belongs to the latter, that is, the three screws are arranged in a triangular shape.

Features of Three-screw Extruder :

- 1. High output and low energy consumption.

- 2. The two screws of the twin-screw extruder form one meshing surface, while the three screws of the three-screw extruder form three meshing surfaces, that is, the meshing area of the screws of a three-screw extruder is equivalent to three sets of the same power twin-screw extruders' screw meshing area, so the extrusion efficiency and shearing efficiency is high, and its output is twice that of the twin-screw extruder with the same power. To produce the same quantity of products, the cost of manpower, space, etc. is doubled reduced. And it saves energy because the power of the main motor, heating coil and other components is reduced.The gearbox has a long life Compared with the inside of the double-screw gearbox, the inside of the three-screw gearbox has one more force point, the force area of the gearbox increases, and the corresponding pressure decreases, thereby prolonging the life of the gearbox.

- 3. Self-cleaning function The machine has an automatic cleaning function, and the waste in the barrel can be cleaned without removing the screw when the machine is stopped.

- 4.Other characteristics:

- The main machine adopts advanced frequency converter speed regulation technology, which makes the equipment powerful, runs more smoothly and saves electricity.

- The screw is treated with alloy steel nitriding, the life of the screw is longer, and the individual equipment adopts the building block combination structure, which can be combined arbitrarily according to different needs.

- Forced lubrication system to ensure a longer life of the transmission part of the equipment.

Technical Parameters :

For making pet food

| Model | Installed Power | Main Motor Power | Capacity | Dimension |

| TSE65-III | 58kw | 45kw | 300kg/h | 2480x800x1300mm |

For making puffed snacks

| Model | Installed Power | Main Motor Power | Capacity | Dimension |

| TSE65-III | 58kw | 45kw | 250kg/h | 2480x800x1300mm |

For making puffed snacks

Two-color Puffed Food Extruder

The two-color puffed food extruder has been transformed and upgraded on the basis of the ordinary twin-screw extruder, so that it has a larger output than the ordinary twin-screw extruder, and the same machine can produce two colors of puffed food and pet food. In the past, in order to obtain two colors of products, manufacturers need to mix two kinds of finished products, or two core machines produce at the same time, and then mix products of different colors. The emerge of this two-color food extruder perfectly solves such problems. What's more, it can produce one product with 2 colors, which cannot be achieved by previous technical means. Our company is the inventor of this technology and has applied for related technology patents.

Technical Parameters :

| Model | Installed Powder | Main Motor Powder | Capacity | Dimension |

| TD-I | 68kw | 55kw | 300-500kg/h | 2520x850x1300mm |