Series of Pasta Processing Line

Pasta Macaroni 3D Snacks Processing Line

- 1. Frying Pellet Processing Line adopts flour, corn starch and potato starch as raw material, makes food through the process of extruding, cooking, shaping, drying and frying.

- 2. By choosing different dies, you can make different shapes food such as shell, screw, square tube, round tube, lotus root slices etc. The food is very popular in market.

- 3. This processing line has the advantage of rational design, high automatic degree and accuracy control.

- 4. The model is EXT100, the output is 100-120kg/h.

- 5. The main body material is stainless steel, which is easy to be cleaned.

- 6. The screws material is 38CrMnAl, which is wear-resisting.

- 7. Our project is turn-key. We will send our engineer to your factory, install and debug the equipments, and train your operators.

- 8.The processing line needs two workers to operate.

- 9. Around 100 square meters plant is suggested for this line. The length is no less than 20 meters.

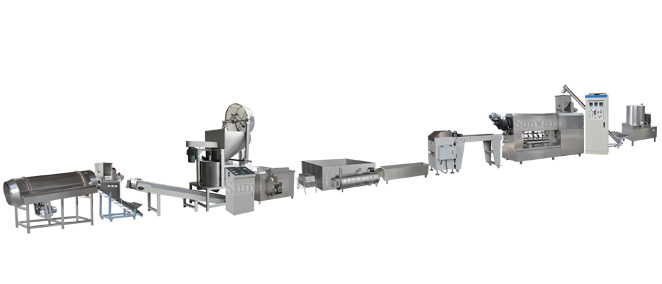

- 10. Process flow: (Raw material)---mixing---extruding & puffing---cooling---drying---frying---hoisting---flavoring--- (packing)

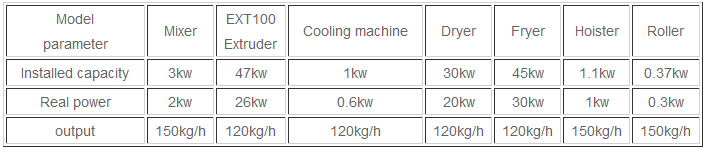

- 11. Machines: Mixer---Extruder---Cooling bed---Drying bed---Fryer---Hoisting and flavoring machine---Roller--- (Packing machine)

- 12. The temperature and rotating speed can be controlled and adjusted.

Spaghetti Processing Line

Spaghetti is a staple food of traditional Italian cuisine, and now it is popular in many countries. It is a kind of long, thin, solid, cylindrical noodle pasta. Like other pasta, spaghetti is made of milled wheat and water and sometimes enriched with vitamins and minerals. Italian spaghetti is typically made from durum wheat semolina.

Our spaghetti production line is a new type of machinery to produce spaghetti. Compared with the common spaghetti production line, our equipment requires less space, less manpower, and higher production efficiency.

Flow chart:

Mixing system---Extrusion system----cooling system----Drying system----Packing system

Customization:

We manufature machines according to customers' Local voltage according to customers' needs. For example, motors of different voltages and brands.

Service:

Free consultation, free program design, engineers go abroad for field service, also have on-line guidence service.

Features:

All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel.

Technical Parameters :

| Model | EXT100 | EXT100-N | TSE75 |

| Installed Power | 130kw | 170kw | 200 |

| Production Capacity | 80-120kg/h | 120-200kg/h | 200-300 |

| Dimension(L*W*H) | 20*1.6*2.2m | 30*2.0*2.6m | 26*1.6*2.6m |