Series of Pet Food Processing Line

Pet Chews Production Line

Pet chews take starch as raw materials with scientific configuration and was extruded from an extruder. It can be made into different kind of shapes such as sticks, bones,bi-flavor, etc. This kind of food not only provide protein, fat, vitamin, and nutrition for dogs but also satisfy the dog nature hobby. It has the following features: strong teeth, cleaning mouth, and teeth. The products can be in many shapes, like twists, double colors,cor-filling, and so on.

Technical Parameters :

| Model | installed Power | Production Capacity | Dimension |

| EXT100 | 70kw | 80-120kg/h | 27×2.0×2.2m |

| EXT130 | 100kw | 150-200kg/h | 30×2.0×2.3m |

| TSE75 | 140kw | 200-300kg/h | 32×2.5×2.8m |

| TSE78 | 170kw | 400-600kg/h | 36×2.5×3.0m |

Floating & Sinking Fish Feed Processing Line

The fish feed production line can produce premium quality floating and sinking fish feed and pet food, such as special koi food, goldfish food, catfish food, tropical fishes food, cat food, as well as dog and monkey food. This production line adopts the steam method with high-efficiency driving, stable and low noise. The products produced by this production line have the characteristics of high protein, complete nutrients, long floating on the water surface, etc., and can be added with micronutrient elements, which can promote the rapid growth of pets and fish, and are well received by farming enterprises. The production line has a high degree of automation and large output. It is an ideal choice for manufacturers who invest in the production of pet food and aquatic feed.

Features :

- 1. The main machine is twin-screw extruder. Compared with the single screw extruder, it has a high degree of automation, stable performance, good product quality and large output.

- 2. The forced lubrication system, can guarantee the equipment transmission life longer.

- 3. Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

- 4. Self-cleaning, when stopping, it can be cleaned without disassembling.

- 5. Through the pretreatment of the fodder, it can reduce loss of nutrition and advance the protein ratio. So the fodder will be digested easily by animals.

- 6. The processing line adopts corn flour, wheat flour,low temperature soya flakes meal, rice bran , wheat bran as raw materials

- 7. Puff snacks, pet food, floating and sinking fish feed pellets can be produced. For floating fish feed, it can float around 20 hours.

- 8. The diameter of fish feed from 0.5mm-15mm is available.

- 9. Sinking and floating fish feed can be shifted.

- 10. Formula will be provided according to customer's demand.

Flow chart of fish feed production line:

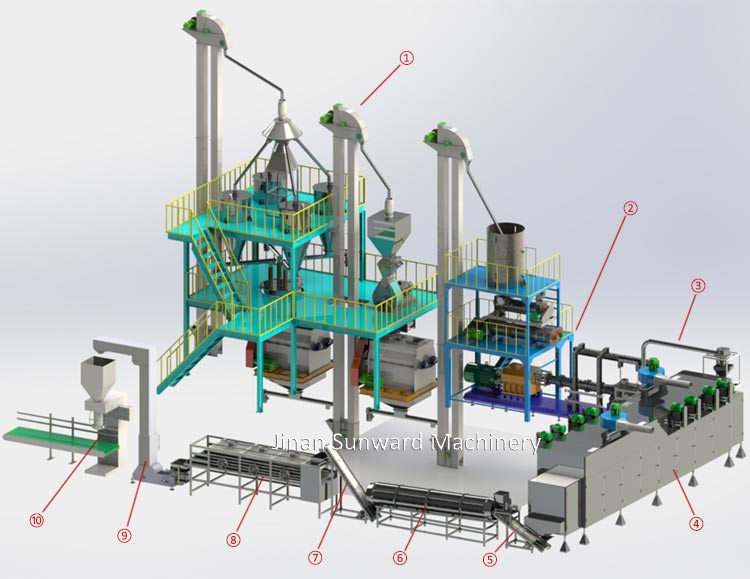

1. Large Scale :

- The raw material processing system of the production line. Its function is raw material pulverizing, weighing and mixing.

- The twin-screw extruder is used for curing, puffing, and forming raw material (There is a pre-conditioner contained in the extruder that is used for pre-conditioning and pre-heating the raw materials through steam, the raw materials are softened, which is more conducive to molding, and at the same time reduces the wear and tear of the raw materials to the extruder machine).

- The Air conveyor is used to deliver fish feed from the extruder to the dryer.

- The dryer is used to dry fish feed. According to the different energy sources, we have electric dryers, steam dryers, oil/gas dryers for you to choose from.

- The Hoister is used to deliver fish feed from the dryer to the flavoring machine.

- The seasoning machine is used to spray the surface of the fish feed with drugs for treating fish diseases and attractants, etc.

- This is another Hoiser which is used to deliver fish feed from the seasoning machine to the cooling machine.

- The Cooling machine is used to cool fish food before packing.

- The Z Shape Hoister is used to deliver fish feed from the cooling machine to the packing machine.

- The packing machine is used to pack fish food in different bags. We have fully automatic and semi-automatic packing machines for you to choose from. Powder, granular and blocky products can be packed by the packing machines.

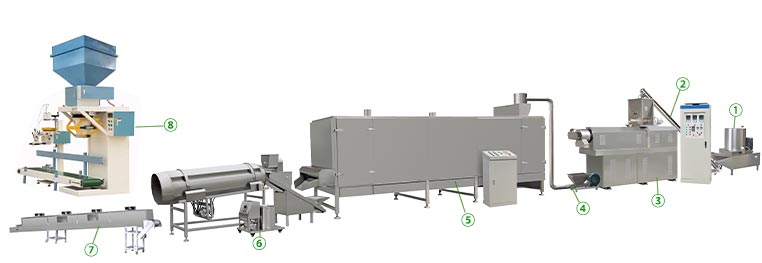

2. Small Scale:

- 1. Mixer

- 2. Screw conveyor

- 3. Twin-screw extruder

- 4. Air conveyor

- 5. Dryer

- 6. Single-drum flavoring line

- 7. Cooling machine

- 8. Packing machine

Technical Parameters :

| Model | Power | Consumption | Output | Installation Size |

| TSE65-P(Dry) | 74kw | 22-30kw/h | 100-200kg/h | 17×1.5×2.2m |

| TSE70-P(Dry) | 105kw | 30-35kw/h | 200-300kg/h | 20×1.5×2.2m |

| TSE85-P(Dry) | 160kw | 60-65kw/h | 400-500kg/h | 30×1.5×2.6m |

| TSE85(Steam) | 160kw | 60-65kw/h | 500-800kg/h | 20×1.5×2.6m |

| TSE95(Steam) | 180kw | 80-95kw/h | 1000-1500kg/h | 39×2.0×3.5m |

| TSE120(Steam) | 245kw | 128-150kw/h | 2000-3000kg/h | 45×2.0×3.8m |

| TSE140(Steam) | 280kw | 200-240kw/h | 3000-5000kg/h | 78×38×4.2m |

Large Capacity Pet Food Processing Line

Pet food is a nutritious food specially provided for dogs, cats, fish and other pets. It is a high-end animal food between human food and traditional livestock and poultry feed. Usually what we call pet food is dry puffed pet food, which is a kind of commercial pet food.

The pet food produced by the puffing process has the following advantages:

- 1. Improve the palatability of pet food;

- 2. Change or improve the nutritional value of pet food;

- 3. Improve pet's digestion and absorption rate of food;

- 4. Change the shape and structure of pet food to make it easy for pets to eat;

- 5. Change the content of different nutritional indicators of pet food, such as reducing the moisture content in order to improve the shelf life of the food, which is conducive to storage;

- 6. Change the bulk density of food, squeeze granulation, briquetting to increase the bulk density of food;

- 7. Kill all kinds of molds, salmonella and other harmful substances, and improve the safety and hygiene of pet food

Extrusion can be divided into two types, one is the dry expansion method, and the second is the wet expansion method.

Dry puffing requires the addition of water to the raw materials during the production and processing. The raw materials do not undergo pre-conditioning treatment before entering the puffing bin. The heat generated during the puffing process is all from the raw materials through the screw and shear plate under the action of mechanical extrusion. And produced in the puffing cavity.

The difference between wet puffing method and dry puffing method is that the raw materials are prepared in advance before entering the puffing method, and the temperature is increased by steam or water, and pre-cured. The so-called conditioning refers to the use of steam to heat and moisturize pet food raw materials to pre-gelatinize, protein denature, and soften raw materials in the raw materials, which is beneficial to improve the puffing and granulating effect of pets and improve the puffing quality.

Our pet food machines have the capability of these two puffing processes. But in general, small-volume machines only have the capability of dry puffing.

Features of our pet food machines :

- 1. In the extruder, the ingredients are cooked under intense heat and pressure as it moves toward the open end of the extruder where ingredients pass through a shaping die and knife.

- 2. Pet Food Processing Line adopts corn flour, bone meal, fish meal as raw materials

- 3. Different shapes can be made by adjusting the dies from extruder

- 4. Output can be 1ton---3.5ton/h

- 5. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

- 6. All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

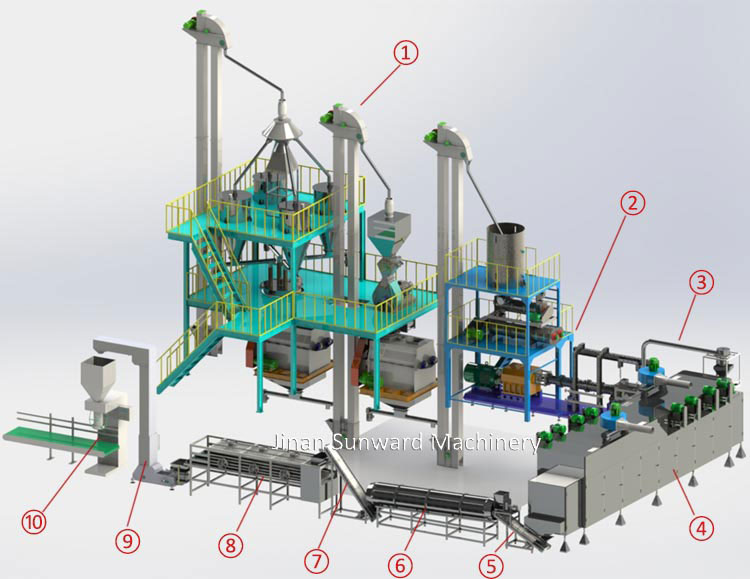

Flow Chart:

Raw material processing system---Extrusion system----Drying system----Flavoring system--Cooling system--Packing system

- The raw material processing system of the production line. Its function is raw material pulverizing, weighing and mixing.

- The twin-screw extruder is used for curing, puffing, and forming raw material (There is a pre-conditioner contained in the extruder that is used for pre-conditioning and pre-heating the raw materials through steam, the raw materials are softened, which is more conducive to molding, and at the same time reduces the wear and tear of the raw materials to the extruder machine).

- The Air conveyor is used to deliver fish feed from the extruder to the dryer.

- The dryer is used to dry fish feed. According to the different energy sources, we have electric dryers, steam dryers, oil/gas dryers for you to choose from.

- The Hoister is used to deliver fish feed from the dryer to the flavoring machine.

- The flavoring machine is used to spray the surface of the fish feed with drugs for treating fish diseases and attractants, etc.

- This is another Hoiser which is used to deliver fish feed from the seasoning machine to the cooling machine.

- The Cooling machine is used to cool fish food before packing.

- The Z Shape Hoister is used to deliver fish feed from the cooling machine to the packing machine.

- The packing machine is used to pack fish food in different bags. We have fully automatic and semi-automatic packing machines for you to choose from. Powder, granular and blocky products can be packed by the packing machines.

Technical Parameters :

| Model | TSE90 | TSE95 | TSE120 | TSE135 |

| Installed Powder | 160kw | 180kw | 245kw | 290kw |

| Production Capacity | 800-1200kg/h | 800-1500kg/h | 2000-3000kg/g | 3000-5000kg/h |

| Dimension | 40*2.0*3.0m | 45*2.0*3.2m | 60*3.0*3.5m | 78*3.8*4.0m |

Small and Medium Capacity Pet Food Processing Line

Pet food is a nutritious food specially provided for dogs, cats, fish and other pets. Its function is mainly to provide pets with the most basic life guarantee, growth and health required nutrients. It has the advantages of comprehensive nutrition, high digestion and absorption rate, scientific formula, quality standard, convenient feeding and prevention of certain diseases.

Generally speaking, the pet food we often see and talk about in our daily life refers to dry-type puffed pet food, which also belongs to commercial pet food. It is a pet food that is made by mixing many nutrient materials, then puffing or extruding, and then drying, dehydrating, and seasoning. The moisture content is generally below 12%. This type of food is comprehensive and balanced due to its comprehensive nutrition. It has a long shelf life, convenient feeding and carrying, affordable price and more and more accepted and sought after by people. At the same time, it also has the characteristics of easy digestion and absorption. The digestibility of this type of dog food can reach about 70%. In addition, the unit heat energy can reach 6.27~6.69KJ/kg, which is very rich in energy. Because of this, this kind of dog food has penetrated more and more into many families with pets.

Features of our pet food machinery :

- 1. In extruder, the ingredients are cooked under intense heat and pressure as it moves toward the open end of the extruder where ingredients pass through a shaping die and knife.

- 2. Pet Food Processing Line adopts corn flour, bone meal, fish meal as raw materials

- 3. Different shapes can be made by adjusting the dies from extruder

- 4. Output can be 100kg/h---1ton/h

- 5. Self-cleaning, when stopping, it can be cleaned without disassembling.

- 6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

- 7. All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

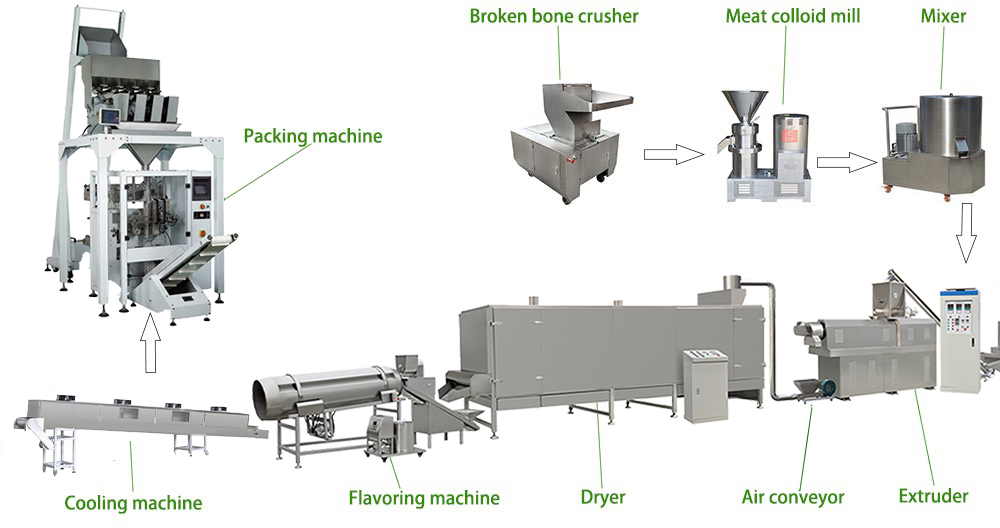

Flow chart:

Broken bone crusher---Meat colloid mill---Mixer---Pet food extruder---Air conveyor---Dryer---Flavoring machine---Cooling machine---Packing machine.

- The broken bone crusher, which is used to grind animal bones (such as cow bones, pig bones, and chicken bones into bone grits).

- The meat colloid mill is used for milling small bone and meat into paste.

- The mixer is used for mixing raw materials.

- The pet food extruder is used for curing, puffing, and forming raw material. Normally the big size of extruders contain a pre-conditioner which is used for pre-conditioning and pre-heating the raw materials through steam, the raw materials are softened, which is more conducive to molding, and at the same time reduces the wear and tear of the raw materials to the extruder machine.

- The air conveyor is used to deliver products.

- The dryer is used to dry pet food. According to the different energy sources, we have electric dryers, steam dryers, oil/gas dryers for you to choose from.

- The flavoring machine is used to flavor pet food. This is a twin-drum flavor that is used to add powder or liquid condiments to pet food. We also have single-drum flavors and eight-square flavors for you to choose from.

- The cooling machine is used to cool pet food before packing.

- The packing machine is used to pack pet food. We have fully automatic and semi-automatic packing machines for you to choose from. Powder, granular and blocky products can be packed by the packing machines.

Technical Parameters :

| Model | TSE65-P | TSE70 | TSE75 | TSE85 | TSE90 |

| Installed Powder | 74kw | 105kw | 130kw | 145kw | 160kw |

| Capacity | 100-150kg/h | 200-280kg/h | 300-400kg/h | 400-600kg/h | 800-1000kg/h |

| Dimension | 17*1.5*2.2m | 20*1.5*2.2m | 25*1.5*2.2m | 30*1.5*2.6m | 40*2.0*3.5m |