Series of Snack Food Processing Line

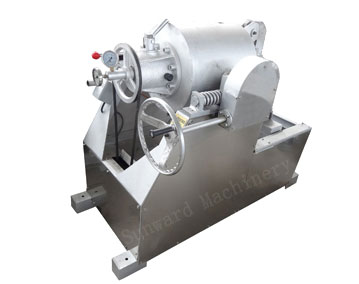

Air Flow Puffing Machine

Air steam puffing machine keeps the selfowned flavors, nutrition and colors of wheat, rice, corn, millet and other cereal grains. It is the best suitable puffing machine for rice cake, wheat cake, coffee corn, sweet cheese rice and other puffed grain foods.

Air flow puffing machine food machine feature:

- 1. Great Output ( about 60kg/h)

- 2. Less Human Power ( one worker can operate two machines)

- 3. Less power consumption (low energy consumption of unit product)

- 4. Simple structure,safe operation and stable performance.

- 5. Good performance and high speed

- 6. Excellent product quality and good taste.

Air flow puffing machine food machine Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers local voltage according to different countries.

Air flow puffing machine food machine material: All the machins are made by stainless steel.

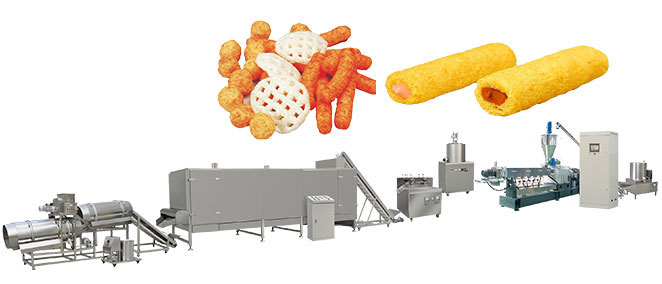

Puff Snacks Processing Line

- 1.Puff Snacks Processing Line can take corn, rice, wheat, oat, rye and other grains as materials to produce extruded snacks, with crispy taste and lively shape.

- 2.Different shapes of snacks can be produced such as Round, triangle, square, stars, flower, etc

- 3.The processing line is from feeding, extruding, core filling, shaping ,cutting , oil spraying to finished products are done once time automatically.

- 4.This processing line can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruels, nutrient-flour, and baby food and so on.

- 5.The screws are made by ally steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.

- 6.The forced lubrication system, by guaranteed equipment transmission longer life.

- 7.Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

- 8.It also can be designed according to customer requirement;

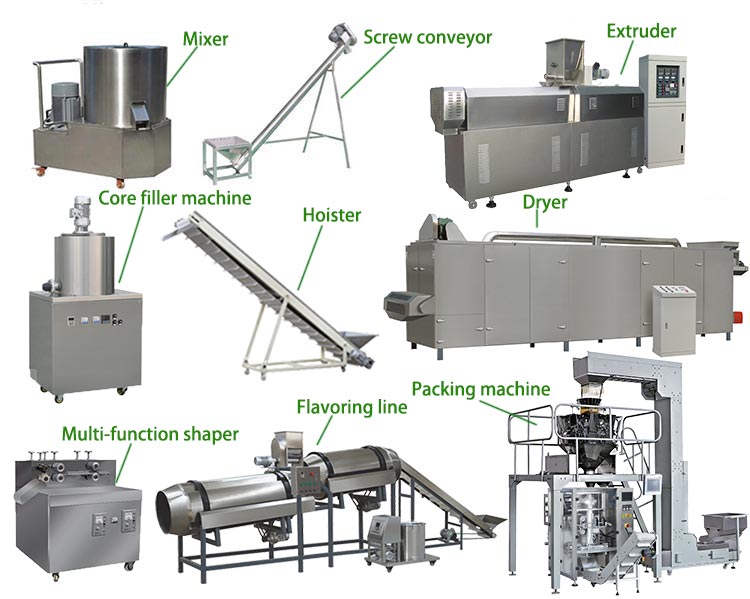

Flow Chart :

Mixer---Screw conveyor---food extruder---Core filler machine---Multi-function shaper---Hoister---Dryer---Flavoring line---Packing machine

The mixer is used for mixing raw materials.

The screw-conveyor is used for delivering well-mixed raw material from mixer to food extruder.

The food extruder is used for curing, puffing, and forming raw material. Normally the big size of extruders contain a pre-conditioner which is used for pre-conditioning and pre-heating the raw materials through steam, the raw materials are softened, which is more conducive to molding, and at the same time reduces the wear and tear of the raw materials to the extruder machine.

The core filler machine is used for filling fillers (such as chocolate, jam, cream) to the snack food.

Multi-function shaper is used for forming different shape of snack food.

The Hoister is used for delivering products from Multi-function shaper to the dryer.

The dryer is used for drying snack food. According to the different energy sources, we have electric dryers, steam dryers, oil/gas dryers for you to choose from.

The flavoring machine is used for flavoring snack food. This is a twin-drum flavor that is used to add powder or liquid condiments to snack food. We also have single-drum flavors and eight-square flavors for you to choose from.

The packing machine is used to pack pet food. We have fully automatic and semi-automatic packing machines for you to choose from. Powder, granular and blocky products can be packed by the packing machines.

Technical Parameters :

| Model | TSE65 | TSE70 | TSE75 | TSE85 | TSE95 |

| Installed Power | 74kw | 74kw | 160kw | 170kw | 195kw |

| Capacity | 100-150kg/h | 200-260kg/h | 300-400kg/h | 400-500kg/h | 800-1200kg/h |

| Dimension | 17000×1500×2200mm | 17000×1500×2200mm | 25000×1500×2200mm | 30000×1500×2600mm | 40000×2000×3500mm |

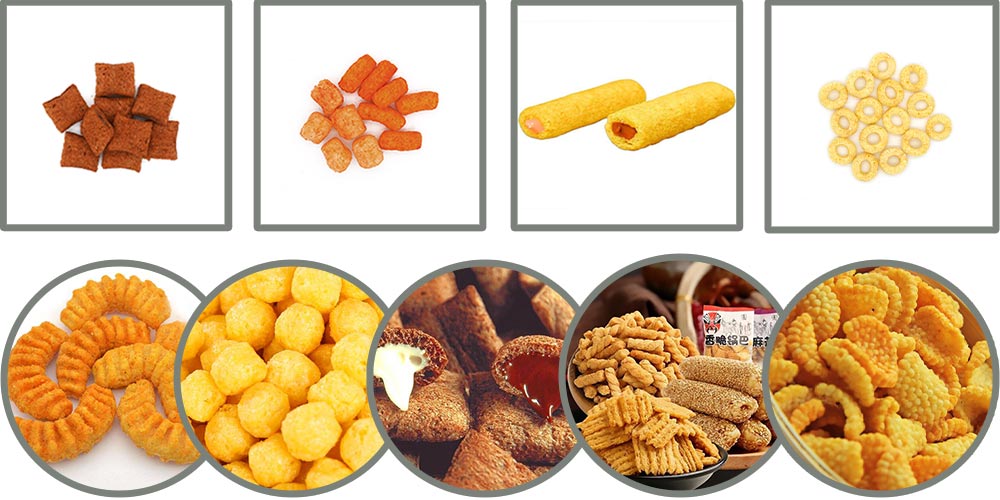

Product Samples:

Nik Naks Kurkure Processing Line

Kurkure/ Cheetos are special extruded snacks with crunchy and great taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixed with water and fed to the Rotary Head Extruder. Due to the two rotary plates, corn grits are squeezed and twisted to curls shapes. The cutting knifes can cut into required lengths. The Kurkure/ Cheetos can be fried in cooking oil or toasted in oven and then cooled before flavoring. Seasoning is sprayed on the surface to achieve different favorable tastes. Due to the delicious flavors and nutrition, it is quite popular with consumers.

Features :

- 1. Raw materials: adopts corn grits as raw materials.

- 2. Products: The production lines are dedicated to produce cheetos/kurkure/nik naks snacks.

- 3. Capacity: 100--150kg/h

- 4. Flow chart: Mixing system---Extrusion system----Baking system (Frying System) ---Flavoring system---Packing system

- 5. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

- 6. Machines Materials: All the machines are made by stainless steel

Technical Parameters :

| Model | Type | Installed Power | Output | Dimension |

| EXT76 | Frying | 85kw | 100-150kg/h | 21×1.8×2.1m |

| EXT76 | Roasting | 80kw | 100-150kg/h | 18×1.8×2.1m |

Fried Snacks Production Line

This production line can make different kinds fried snacks(such as rice crusts,chips,bulges,pizza rolls,Doritos)based on changing die moulds and manufacturing technique. The production process includes mixing ,extruding,cutting,frying,flavoring and packing ,The products are crispy and less oil.

Technical Parameters :

| Model | TSE65 | TSE70 | TSE75 | TSE85 |

| Installed Power | 88kw | 126kw | 190kw | 180kw |

| Capacity | 100-150kg/h | 200-260kg/h | 300-400kg/h | 300-500kg/h |

| Dimension | 21000×1600×2200mm | 30000×1600×2200mm | 35000×1600×2600mm | 30000×1600×2600mm |